Covent opt for Bitzer compressors

NORWAY – Covent, the leading producer of ventilation units with and without cooling in Norway, have been on the lookout for suitable capacity control since as long ago as 2012. Covent now believe that they have found the solution to their capacity control issues and have chosen to work with the compressor manufacturer Bitzer.

The company is based in Bjerkreim, a small community in the southwest of Norway, and has over 40 years of experience in the production of ventilation units. The 100 people employed by Covent produce around 1,200 ventilation units each year. The units produced by the Norwegian company generally offer displacement of between 1,000 and 100,000 m3/h, while the annual turnover of the factory in Bjerkreim amounts to 20 to 25 million euros.

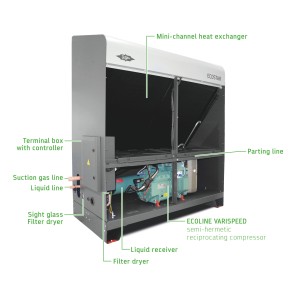

The new Covent line now comes equipped with Bitzer’s Ecoline reciprocating compressors and CRII capacity control since August 2015 – with a production volume of around 150 compressors per year. The company now install Bitzer’s reciprocating compressors and capacity control as standard in all ventilation units with integrated cooling.

“Many of our units have variable ventilation volumes, so we need a cooling system that works reliably with both high and low air streams and can be flexibly adjusted by capacity control,” declared the Technical Manager at Covent, Jostein Jensen. “The decisive improvement for us is that we no longer have three-step capacity control for two compressors as we did previously – but rather, each individual Ecoline reciprocating compressor is variably controllable. That increases system efficiency and reduces installation costs. That is why we replaced the existing compressors with the Ecoline with integrated CRII from Bitzer.”

Covent had a very specific demand for their compressors – they wanted a solution with a capacity regulator for a broad area of application and with very high system efficiency, while also seeking easy to operate and reliable devices. They are confident that Bitzer’s tailored combination of Ecoline and CRII will meet their needs. Bitzer claim that the compressor with their CRII system is almost infinitely variable depending on the operating conditions and refrigerant thanks to an adjusted control algorithm which allows the compressor to be adjusted to suit all operating conditions.

“We had been looking for the right compressor with integrated capacity control since 2012, but we hadn’t found it until we came to Bitzer,” commented the Covent sales manager, Johan Jakobsen. “That is why we entered negotiations immediately and were able to start the project in early 2015. The combination of Ecoline and CRII is ideal for us and also opens up many options for the future. We are in close contact with Bitzer in that regard.”

The Swedish company Regin also were involved in the project, as they specially adjusted their controllers to the system requirements of CRII so that both work together optimally. The first Covent ventilation units to use Bitzer reciprocating compressors in conjunction with CRII were shipped to customers at the beginning of August 2015.

“With the CRII system, which has been improved with blocked suction, the ECOLINE reciprocating compressors can be completely individually and flexibly adjusted to the required operating conditions,” added Ralf Gasper, Director of Sales in Northern Europe and the Baltic States for BITZER. “In this way, BITZER increases system efficiency and reduces strain on the environment, and customers save on operating costs.”