BITZER at Climatización in Madrid

SPAIN – Compressor specialist BITZER showcases its pioneering innovations in refrigeration and air conditioning technology at this year’s Climatización trade fair in Madrid.

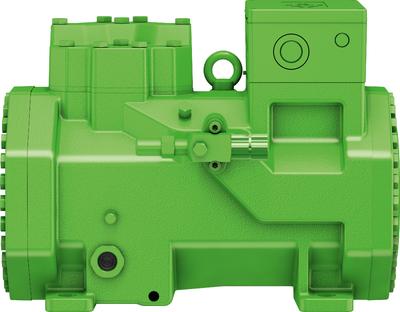

One of the highlights of the BITZER stand at Climatización is the eight sub-critical CO2 reciprocating compressors of the CME series, which are extremely versatile and can be used as boosters or in water cooled systems in both low and medium temperature applications.

Since they can accommodate a displacement between 1.7 and 9.22 m3/h and are available with two different motor versions, the compressors are exceptionally versatile and can be adjusted in line with any capacity requirements. Equally, the new cylinder head facilitates an extremely low pressure pulsation.

ASERCOM awards Bitzer compressors a rating of very good

BITZER is the sole compressor manufacturer whose performance data has been certified by the Association of European Refrigeration Component Manufacturers (ASERCOM). Almost all compressors used in sub-critical CO2 applications and the majority of the compressors for trans-critical applications have been integrated within the certification program. The efficiency of the system and thus the compressor itself merit further investigation.

While the version 2 motor primarily boasts higher standstill pressures, the version 1 motor expands the range of applications of the CME two-cylinder in terms of evaporation and also condensing temperature. In addition the CME series combines the proven efficiency and the reliable drive gear technology of BITZER SL compressors with an exceptionally high strength pressure of 100 bars of standstill pressure, while maintaining operating reliability at all times. Further improvements include an optimised oil barrier and new suction gas guidance. Having a maximum condensing temperature of 25°C, the CME series is also ideal for use with chilled water distribution nets.

BITZER presented the new OS.A95 screw compressor, which is specially designed for industrial ammonia applications, to a specialist audience at Climatización. Accomodating a displacement of up to 1,015 m3/h at 50 Hz, the application spectrum of the OS.A95 models ranges from air conditioning and medium temperature applications to the low temperature refrigeration range, due to the enhanced carriage profiles with optimised flow cross sections.

OS.A95: electronics enabling perfect slider control

A key component of the OS.A95 is the integrated smart electronics component CM-SW-01 which, in conjunction with the Vi slider, can be used to efficiently and infinitely adjust the volume ratio over a wide range of applications. This is made possible using integrated sensors and a slider position indicator. The electronics also reliably monitor the application limits, the feasible temperatures of the compressor and the oil supply. The master system controllers also contain Modbus-based communication interfaces.

The integrated seamless slider control with position indicator allows the compressor capacity adjustment to be optimised in line with system requirements. Internal oil management, which arises from the CSH series, is also employed here, using exceptionally low oil circulation rates and differential pressures to ensure reliable and extremely efficient oil lubrication for the compressor.

Flexibility is paramount: combining uneven scroll compressor sizes in a parallel circuit for use in air conditioning and heat pump systems

The patent-pending BITZER Advanced Header Technology (BAHT) is designed for use in scroll compressor tandems and trios and makes it easier to combine uneven compressor sizes in a parallel circuit in air conditioning and heat pump systems. The recently developed suction gas header with integrated oil distribution is a major factor in this improvement, directing oil to one of the compressors in the tandem and trio units, from where it is distributed among the other compressors. What makes the BAHT system so unique is that this process also works with uneven scroll compressors in one unit or when adjusting the frequency of a single compressor. The system also offers another major advantage: active oil management with an oil separator and oil level regulators is no longer necessary. Even when a compressor is turned off, the BITZER Advanced Header Technology maintains oil distribution in the unit.

Intelligent and systematic cooling

Trade fair visitors will be able to see an air cooled BITZER ECOSTAR condensing unit, which adapts the cooling capacity to best suit actual requirements using the speed control of the compressor and fan. The new ECOSTAR generation LHV7E already fulfils the more stringent requirements of the EU Ecodesign Directive, which takes effect in 2016. Precise temperature control helps to increase the efficiency of the refrigeration system and reduces operating costs, while the sound-optimised airflow ensures a low noise level.